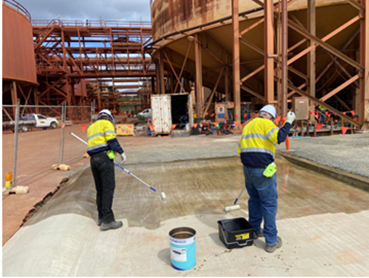

OVERVIEW: Chemcote was contracted to apply acid protection to a newly constructed delivery and storage tank bund. We developed a comprehensive acid-resistant and anti-slip solution that provides the owner long-term peace of mind and ensures this asset will be protected for years to come.

INDUSTRY

Aluminum Refinery

ENVIRONMENT

98% Sulphuric Acid

SUBSTRATE

New Concrete

CHALLENGE

The asset owner required internal protection for their new 500m² delivery bund and storage tank area

SOLUTION

Acid etch all surfaces to be coated to achieve a suitable ‘key” for coatings application

Thoroughly rinse all surfaces to neutralize the surface prior to the application of coatings

Apply one coat of RH 800 @ 100µm DFT

Repair cracks and holes using compatible epoxy filler

Apply one coat of RF 500 Blue @ 250µm DFT – 300µm DFT

One coat of RF 500 Grey @ 200µm DFT – 250µm DFT whilst introducing a non-slip medium during application

Finish with one full coat of RF 500 Grey @ 150µm DFT – 200µm DFT

PRODUCTS

Primer- Damp-crete™ RH 800

Finish – Epo-Chem RF 500

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce