OVERVIEW: Environments such as blast furnaces are subject to high temperatures and particulate, which can accelerate the onset of corrosion and erosion. Constant exposure to heat and blast furnace dust over a period time has a damaging impact on steel structures, valves and fittings. This highlights the importance of safeguarding critical infrastructure through preventative maintenance and anti-corrosion solutions.

INDUSTRY

ENVIRONMENT

Blast furnace gas, combined with particulate at elevated temperatures 70degC

SUBSTRATE

Steel

CHALLENGE

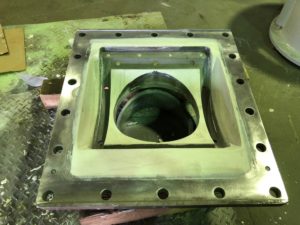

Chemcote were tasked with refurbishing a blast furnace where exposure to gas, particulate dust and elevated temperatures of 70oC were present. A requirement to rebuild the internal profile of a blast furnace was a priority as 10-15mm of steel had been eroded. Applying an effective corrosion protection solution in this harsh environment demanded technical expertise combined with a specialist coating.

SOLUTION

Refurbishing corroded internal components of the blast furnace required a protective coating that offered long-term corrosion and erosion protection. Chem-tect™ RB 364 proved the most suitable product to withstand this particular environment.

The first step was to undertake abrasive blasting of both the internal and external steel structure, while avoiding any damage to the insert sealing ring.

The protective coating was then applied to the internal structure to a minimum of 500µm, followed by pit filling, a cast insert where required, and a second coating of RB 364.

SCOPE

Abrasive blast internals and externals, taking care not to damage the insert sealing ring.

Internal application of RB 364 to a minimum of 500µm

Sand smooth and pitfill with RB 364

Cast insert where required

Application of 2nd coat of RB 364

PRODUCTS

OUTCOME

Following project completion, the coating application coupled with future scheduled inspections delivered long-term protection and an extended life expectancy of the Blast Furnace valve

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce