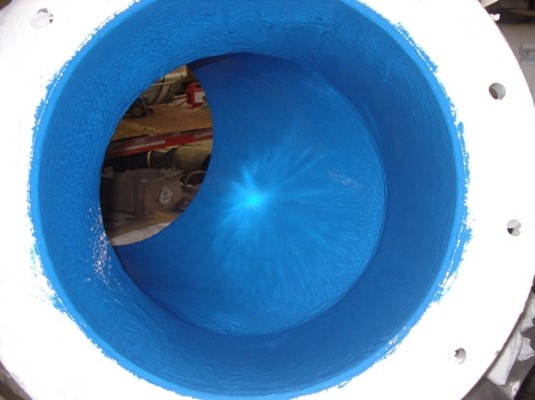

OVERVIEW: The refinery column pump for storm water and effluent required repairs and surface coating to protect from corrosion. Corrosion pitting and erosion was evident in the suction bell & adjoining column and the wear spacer ring/housing.

We recommended rebuilding the internal diameters affected by erosion corrosion to extend column pipe life and return pump to original efficiency

INDUSTRY

ENVIRONMENT

Storm Water, Effluent from Refinery

SUBSTRATE

Column pump

CHALLENGE

Column pump repairs were required and the surface coated to protect from corrosion. Corrosion pitting was evident in the suction bell & adjoining column. Erosion/corrosion was taking place in the wear spacer ring/housing.

SOLUTION

We recommended rebuilding the internal diameters affected by erosion corrosion to extend column pipe life and return pump to original efficiency

SCOPE

Abrasive blast to AS.1627.4 to class 2.5

Masking and protection of critical shaft tolerances

Pitting filled to allow smooth transition and prevent coating defects

Application of RA 532 internal & external

Pit-filled areas within impeller housing to ensure smooth finish

Application of RA 532 at a nominal thickness of 200 µm internal & external

Application of RP 500 internal

Application of Luxathane R ‘N35’ external

OUTCOME

The column pump repairs were timely, returning the unit to service within a week. A new replacement pump had a lead time of 16 weeks. The client was extremely happy thanks to the experienced Chemcote team and the exceptional qualities of the Chemco range.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce