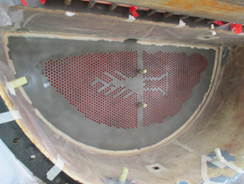

OVERVIEW: The asset owner was looking at extending the life of the condenser tube sheet to prevent galvanic corrosion. We found the water boxes were also experiencing some deterioration. Chemcote were contracted to apply a coating with high insulating properties preventing long term corrosion.

INDUSTRY

Power Generation – Sugar Mill

ENVIRONMENT

40-60°C, brackish / sea water

SUBSTRATE

8 Year Old – Mild Steel water boxes & Stainless Steel tube sheets

CHALLENGE

New tubes were installed in the condenser tube sheet made from an exotic Stainless Steel compared to the low grade tube sheet. We were asked to provide a solution with a coating with a high dielectric strength to prevent the galvanic reaction between dissimilar materials.

SOLUTION

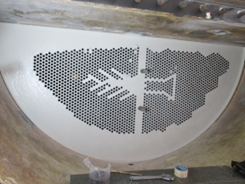

Tube internals were protected by inserting specially designed plastic caps on Inlet/Outlet and Return side of Water Box. This protected the condenser tube sheet.

A glass flake filled vinyl ester was applied to provide excellent permeation resistance and high dielectric strength.

SCOPE

The entire face was hot washed to remove any lubricants and other potential contaminants before abrasive blasting to ensure surface is clean and the correct surface profile is obtained

RB 300 was applied to tube-sheet face, followed by some other areas considered critical, such as the baffle plates, where the existing coating has failed due to under specification

Carried out high voltage spark test beyond Australian Standards to ensure coating integrity

PRODUCTS

Chem-tect™ RB 300 Series, a glass flake filled vinyl ester, provides excellent permeation resistance and high dielectric strength

OUTCOME

The extended life of the coating is expected to exceed 20 years in service, the plant owner is requesting Chemcote to assist further with other corrosion related issues with nearby ancillary equipment.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce