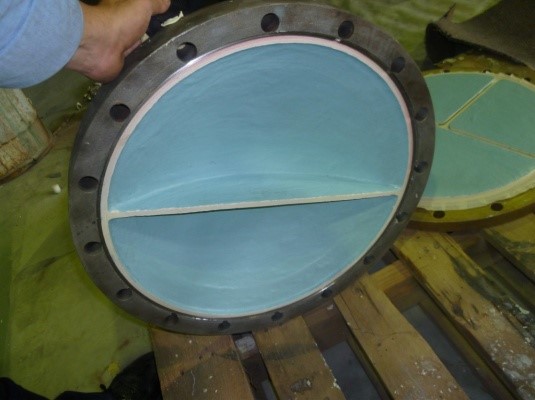

OVERVIEW: The Floating heads and channel end covers were originally coated by another contractor with varying results. Made from exotic materials, they had pitting along the sealing face and localised areas from their environment of salt water at elevated temperature.

RB 332 was applied to the internals to prevent long term corrosion.

INDUSTRY

ENVIRONMENT

Salt water at elevated temperature

SUBSTRATE

Floating heads and channel end covers cast from various exotic materials

CHALLENGE

The end covers were originally coated by another contractor with varying results. Some items were made from exotic materials and had minor pitting along the sealing face and localised areas.

SOLUTION

Prevent long term corrosion by applying RB 332 to the internals of the end covers. Sealing areas showing signs of corrosion pitting were pre-machined to allow for 1mm of coating to be applied and post machined on completion.

SCOPE

High pressure washed internal & externals

Inspection of damaged/heat affected areas

Abrasive blasting to better inspect man hole cover

Pitfill application of RB 332 series in 2 coats

Thickness tested to ensure a minimum of 750µm and holiday test at 6Kv

Externals:

Application of 2 coats of RL 500PF to a nominal thickness of 300µm

Application of 2 coats of N35 Luxathane R

PRODUCTS

OUTCOME

Chemcote delivered a fast turnaround, reducing down-time for the client in the short term and delivering the end covers with expected long term corrosion protection.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce