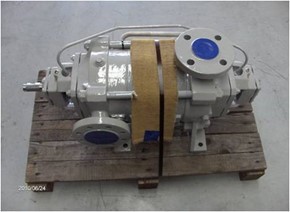

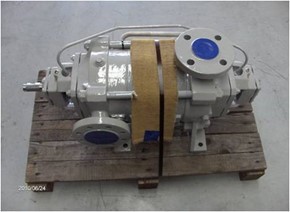

OVERVIEW: Steel multi-stage pump assemblies in an 80°C corrosive aqueous ammonia environment required long term protection.

The external coating system was required to act as a corrosion barrier for the pump case should any leaks occur whilst in service.

INDUSTRY

ENVIRONMENT

80°C corrosive aqueous ammonia

SUBSTRATE

Steel multi-stage pump casing, galvanised coupling

CHALLENGE

The client required an external coating system to provide long term protection to their newly purchased multi-stage pump assemblies against an aqueous ammonia environment at elevated temperatures. The coating system was required to act as a corrosion barrier for the pump case should any leaks occur whilst in service. Abrasive blasting could not be deployed due to the risk of damaging critical components.

SOLUTION

We recommended RL 500PF which primes and finishes in 1 coat. This coating system requires minimal surface preparation. It is moisture/surface tolerant coating is ideal for site maintenance contracts. Rain or high humidity has no effect on painted surfaces.

We followed this with RW 500, a solvent-free epoxy Novolac which imparts outstanding protection to metal substrates. It forms a durable barrier resistant to abrasion, erosion, thermal shock, and the most aggressive environments of high temperature and chemicals in immersed and non-immersed conditions.

SCOPE

Mask off seal areas, ID plates and critical exposed fittings

Mechanically prep surface

Solvent wash with MEK

Prime with 1 coat RL 500PF to prepared surfaces

Apply 2 coats RW 500 to a DFT of 400µm

DFT checks, mount onto base frame, assemble coupling guard

PRODUCTS

Epo-chem™ RW 500 – Solvent Free Novolac Epoxy,

OUTCOME

The two product systems applied by skilled applicators resolved the no abrasive blasting issue and currently provides durable protection against a high temperature corrosive aggressive environment

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce