OVERVIEW: Since re-coating Chemcote’s team has ensured the Extension Leveller is now in excellent condition and maintenance costs have also been drastically reduced.

INDUSTRY

ENVIRONMENT

Recycled cooling water

SUBSTRATE

Steel

CHALLENGE

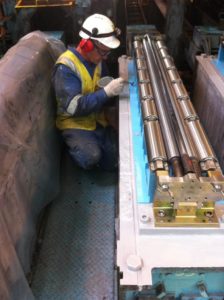

Asset owners of the Extension Leveller Cassette engaged us to inspect and nominate a complete coating solution where standard paint systems failed to prevent surface deterioration resulting in

large refurbishment costs

SOLUTION

RL 500PF is a surface / wet tolerant zinc rich

epoxy, required to a uniform thickness for

smooth functioning

SCOPE

Grind sharp edges and weld porosity

Abrasive blast to AS 1627.4 Class 3, 75µm profile

Application of RL 500PF with nominate thickness 300 microns

Application of 1 coat of RC 500GTC to a final DFT of 400µm

PRODUCTS

OUTCOME

Since re-coating was carried out by Chemcote, the extension leveller has been found to be in excellent condition and maintenance costs have been dramatically reduced

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce

OVERVIEW: Chemcote’s specialist team mobilised to site to deliver a multiple layer protective coating system that would return the asset to working condition within 24 hours. Abrasion resistant coatings were applied to the pugmill and paddles over a 12 hour period during plant shutdown, with 12 hours allocated for curing.

INDUSTRY

ENVIRONMENT

50-70°C 10-40μm abrasive particles from the dust catcher are disposed of in the pugmill and combined with water to suppress the dust creating an abrasive sludge

SUBSTRATE

Steel Substrate

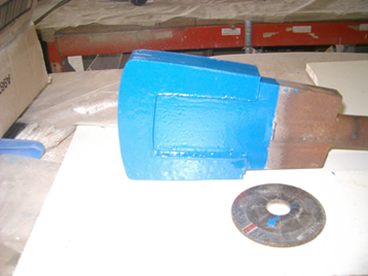

CHALLENGE

Deliver an operational multi coat abrasion resistant coating system within 24 hours

SOLUTION

Thorough surface preparation prior to the application of multiple layers of abrasion resistant coatings. Spot abrasive blasting to minimise disruption to surrounding trades.

SCOPE

Pugmill Internals

Spot abrasive blast localised areas.

Apply of 1 coat of fast curing Chem-tect™ RB 364C to areas where required

Use chopped strands and where deep pitting existed to provide a smooth even profile

Apply 2 coats of Chem-tect™ RB 364CS to 1,000μm

Conduct QA, DFT and high voltage spark test to ensure continuity at required voltage

Paddles

Abrasive blast to AS 1627.4, Class 2.5 with a minimum 75μm profile.

Apply 1 coat of Epo-chem™ RW 500 to a nominal thickness of 500μm to ensure no transparent areas

Complete casting application 1 coat of InD-cote™ to 6000 micron DFT to the load and back faces

PRODUCTS

Paddles coated using Epo-chem™ RW 500 and InD-cote™

Pugmill Internals Chem-tect™ RB 364CS

OUTCOME

Chemcote’s solution has extended the life of this asset by 12-24 months, and delivered a 30% improvement in functioning. Continuous high performance is guaranteed until our review at the next planned outage.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce