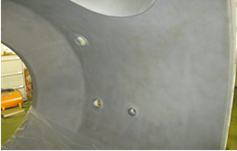

OVERVIEW: The internals of the gas scrubbing pipe were previously lined using a ceramic filled epoxy which was visibly failing with signs of osmotic blisters. Chemcote removed the failed lining and provided long term corrosion protection

INDUSTRY

ENVIRONMENT

40-60°C Saturated Blast Furnace Gas – carbonic acid, which in turn reacts with iron to form iron carbonate and hydrogen gas

SUBSTRATE

Mild Steel Fabrication

CHALLENGE

The internals of the pipe which were previously lined using a ceramic filled epoxy were visibly failing with signs of osmotic blisters. Remove failed lining and provide long term corrosion protection

SOLUTION

Remove the failed ceramic filled lining by UHPWB and carry out further inspection. We recommended the application of RB 300 series@ 1200μm nominal thickness.

SCOPE

Assess on arrival

Abrasive blast to AS 1627.4 2005 Class 3, with a minimum 75μm profile

Hot wash to assist in the removal of metallic salts

Application of 3 coats of RB 300 series

Carry out high voltage Spark Test to ensure coating continuity and DFT checks

External application of RL 500PF in 2 coats

Top coat using RC 500 in two coats in Y44

OUTCOME

Customer saved thousands of dollars in replacement costs. With Chemcote’s application providing long term corrosion protection, many other components have been refurbished using similar methods both on site and within our fully equipped workshop located in Wollongong.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce