OVERVIEW: New 316L pipe failed after just two months in operation, causing a total plant shut down.

Quick response by Chemcote restored production without having to fabricate new pipes.

INDUSTRY

ENVIRONMENT

Ambient temperature seawater

SUBSTRATE

Forged 316L SS elbow & pipe section

CHALLENGE

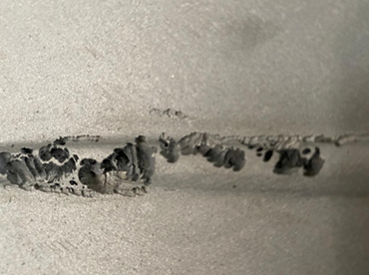

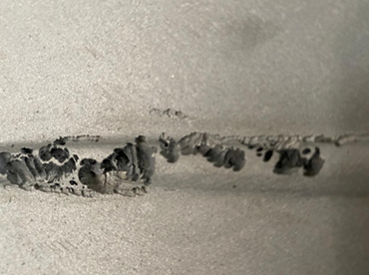

Pitting corrosion in new stainless steel pipes caused holes straight through the steel. Plant unable to operate without these pipes. An immediate and long term solution was required.

SOLUTION

Pipes were removed from service.

Machine rebates to allow coating application onto flange face preventing crevice corrosion.

Apply low MVT (moisture vapour transmission) rated coating, in this case, a glass flake-filled vinyl ester Chem-tect™ RB 364 up to 1,000µm dry film thickness

Reprofile deep pitting holes using composite repair techniques

Reinforce pitted areas and internal lining with basalt fibre weave matting

PRODUCTS

Internals: Chem-tect™ RB 364

Externals: Basalt fibre composite wrap

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce