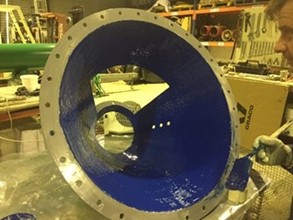

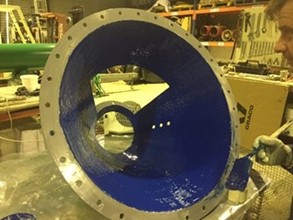

OVERVIEW: Chemco’s Ceram-chem™ system was used to rebuild the internal profile of this valve, and coat to prevent future corrosion and abrasion. In addition, RP 500 creates a slippery surface preventing hang up and blockage issues, maximising the valve’s efficiency.

INDUSTRY

ENVIRONMENT

Coke breeze – abrasive dust

SUBSTRATE

Mild Steel

CHALLENGE

Prevent abrasion, corrosion and hang up.

OUTCOME

A slippery surface preventing hang up and blockage issues. Other valves have now had the same treatment illustrating the asset owners confidence

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce