OVERVIEW: Illustrated a sound understanding of the results required to refurbish and extend the life of heavily corroded equipment. Proven performance after 20 years of using “Chemco International” coatings.

Chemcote has provided long term protection on other strainers and their backwash covers within this power station.

INDUSTRY

ENVIRONMENT

Sea Water

SUBSTRATE

Austenitic iron body

CHALLENGE

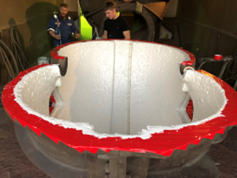

Strainer has been in service for 30 + years. Inspection of the strainer body, back wash covers & critical dimensions found the substrate to be severely corroded, illustrated by the extent of graphitised iron, holes through the casting and diminishing wall thickness

SOLUTION

Composite materials were chosen to rebuild the metal loss. We then applied RB 364 series , a glass flake filled vinyl ester consolidated with composite reinforcing to return the casing to its original strength

SCOPE

Protect threaded holes using backing rod

Abrasive blast and treat to reduce metallic salts by hot washing and re-abrasive blast

Apply Chem-tect™ RB 364 in two coats where required to obtain minimum thickness of 1,000μm

Pitfill to reduce the sharp edges and pit depth allowing a smooth uniform coating to be applied

QA included spark testing and DFT to confirm coating integrity

Apply coat of RL 500 PF to externals

PRODUCTS

OUTCOME

After 15 years of Chemcote Coatings providing long term protection on other strainers and their backwash covers within the power station, Chemcote was enlisted for repairs to the 2 large Strainers to one of the main condenser units

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce