OVERVIEW: Chemcote was requested to perform an emergency reline of failed rubber lined vessel. We mobilised our crew interstate within 48 hours and completed the works within 72 hours.

INDUSTRY

ENVIRONMENT

Demineralised water

SUBSTRATE

10 year old carbon steel vessel

CHALLENGE

The vessel was originally rubber lined. Osmotic blistering found during an inspection raised concerns about metal loss due to the loss of lining integrity. Over the years the rubber lining had been patched & repaired to the point it was no longer serviceable. The vessel would take 2 weeks to replace. Chemcote recommended an alternative solution which was faster and less disruptive.

SOLUTION

On close inspection, deep pitting was found beneath the rubber lining. Weld repairs would have delayed the project so Chemcote recommended pit-filling to be carried out to reduce down time. The RB 300 series was recommended as the coating requires low maintenance and ease of repair-ability. It will also provide 20 years of corrosion protection.

The entire project was carried out on site over a period of 36 hours allowing a fast return to service with minimum disruption to production. The vessel was ready for use 12 hours after completion.

SCOPE

Remove rubber lining

Abrasive blast to AS 1627.4 2005 75

Reduce metallic salts using 90°C high pressure water

All internal and external flange faces are coated to ensure full protection

High Voltage spark test @ 15kV DC & rectify defects

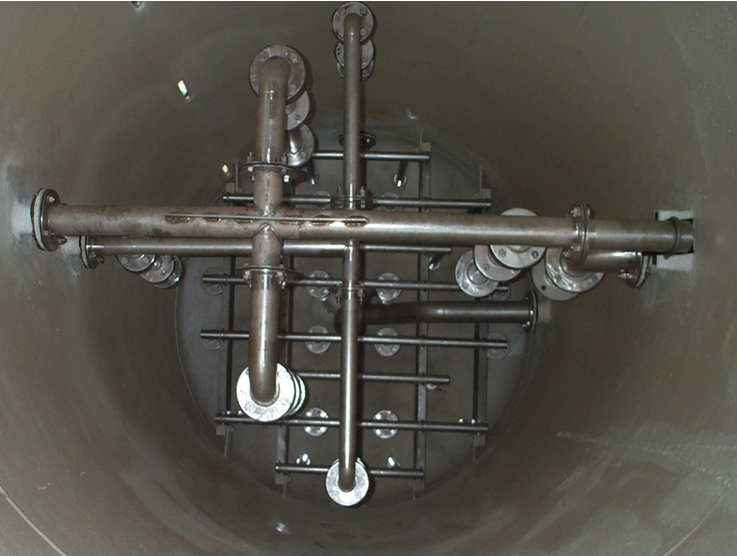

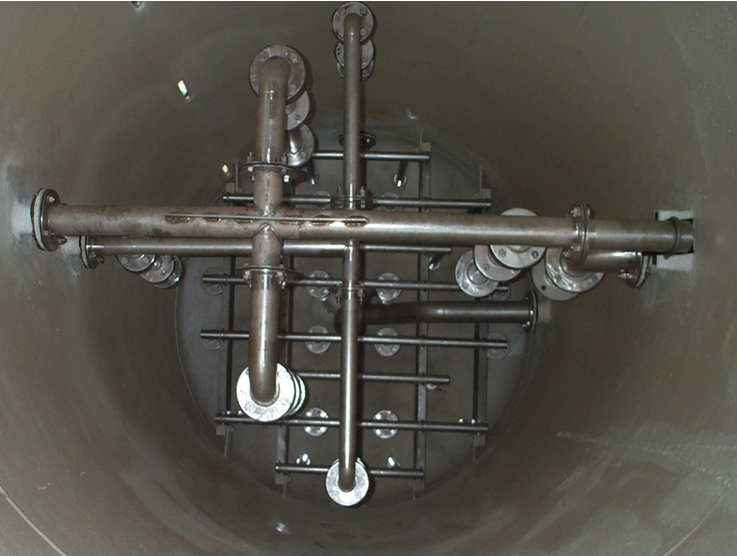

Re-installation of the lateral pipe work

PRODUCTS

OUTCOME

The cation vessel was inspected 18 months and 5 years after original application and found in excellent condition. There were no signs of corrosion or coating breakdown.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce