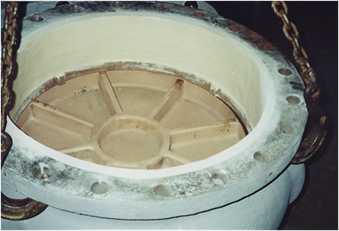

OVERVIEW: The internals of the valve were heavily graphitised and requiring refurbishment with the guide channel for the valve entirely corroded away. A replacement would have taken up to 12 weeks. Chemcote’s refurbishment saved replacement costs and significant delays.

ENVIRONMENT

Sea water

SUBSTRATE

Cast iron Valve body

CHALLENGE

The internals of the valve were heavily graphitised requiring refurbishment as a replacement would have taken up to 12 weeks because this is an imperial non-standard item. Guide channel for the valve was entirely corroded away. Coating and refurbishment had to be completed within 120 hours to prevent disruption to existing shutdown schedule.

SOLUTION

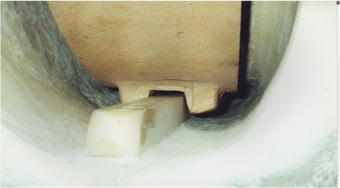

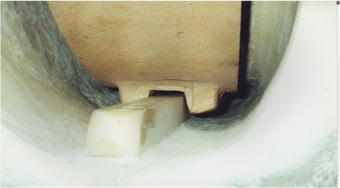

Chemcote recommended RB 300 at 1200μm nominal thickness, a glass-flake filled vinyl ester which provides a tough impermeable barrier that will last in excess of 10 years. Externals finished with top-coat RL 500PF, a moisture and surface tolerant coating.

SCOPE

Protect critical sealing faces

Abrasive blast to remove graphitised metal

Grind rebates on flange faces to allow coating to wrap around preventing crevice corrosion due to misaligned gaskets

Remove graphitised material with air chisel

Hot pressure wash – re-grit blast to AS 1627.4 cleanliness standard with a minimum 75μm profile

Application of 3 coats of RB 300

Install nylon bars to replace corroded guide

Test valve operation

External application of RL 500PF in 2 coats

PRODUCTS

Chem-tect™ RB 300 Series – Internals

Epo-chem™ RL 500PF – Externals

OUTCOME

The valve was refurbished, saving the client replacement costs and waiting time. The client was extremely satisfied with this job and have since awarded other items to be refurbished by Chemcofe using similar methods.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce