Solutions

Chemcote offers wet tolerant solutions for concrete, ferrous or non ferrous substrates or fiberglass. Our water protective coatings are used in cruise ships, tankers, container ships, deep sea fishing trawlers, refrigeration vessels, offshore supply vessels, offshore platforms and anywhere potable water is stored.

Our solvent free, wet and rust tolerant primers and coating solutions can be applied in confined spaces and do not require dehumidification or additional ventilation.

These factors combine to deliver a cost-effective and time effective solution for customers who wish to return assets to full capabilities with minimum down time.

We proudly offer up to 25 years guarantee on selected coating systems.

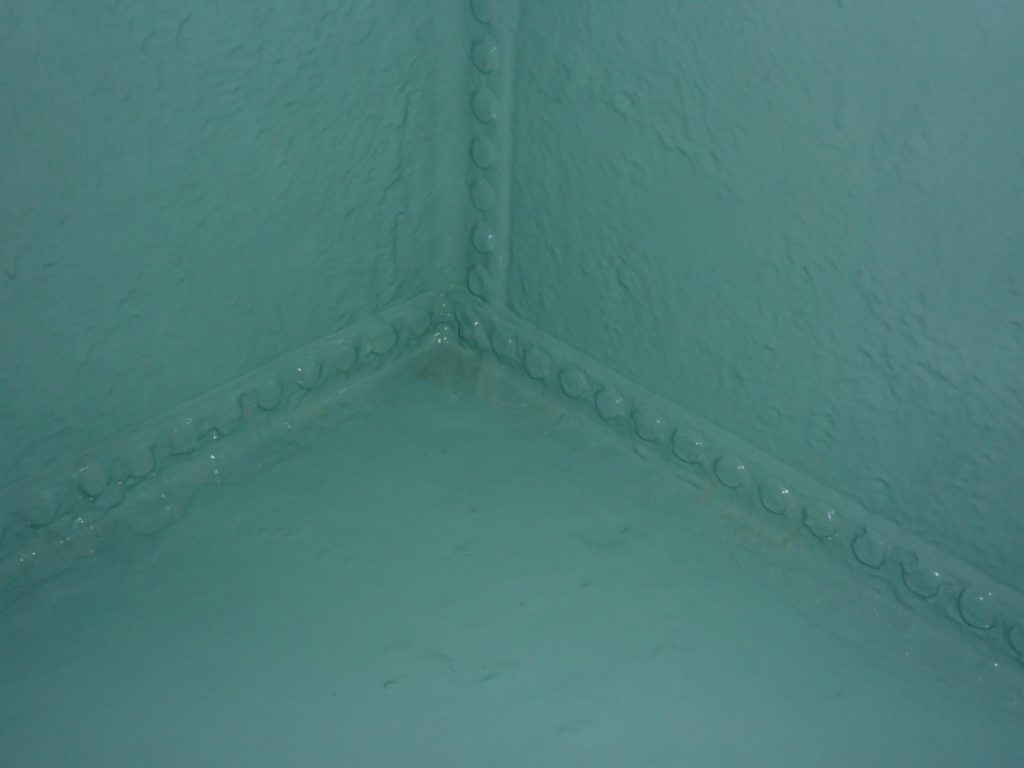

Water ballast tanks (WBT) represent the single largest surface area on any ship and pose unique challenges because they consist of complex, difficult to reach geometrical surfaces and confined spaces that are normally exposed to permanent condensation. De-humidification is often required.

Chemcote offers a unique solution that does not require abrasive blasting and can be applied on wet and rusty surfaces, in dry dock or at sea.

Our system for WBTs consists of a solvent-free, wet & rust tolerant primer and solvent-free, wet tolerant, glass flake epoxy topcoat that is used worldwide for new builds, refurbishment and repairs. This coating system has passed independent IMO resolution MSC.215(82) tests for application in sea water ballast tanks on bare steel and shop primed steel as well as wet & rusty substrates.

Authorised Australian distributor of quality Chemco International Products