Solutions

Approximately 2500 different types of liquids are stored in storage tanks around the world. 52 liquids make up 80% of the liquids in storage. Most commonly these are water, oils, chemicals, solvents, alcoholic beverages and fuels. The coating selection is critical to ensure the correct coating is applied for the material that is being stored. A leak or failure due to corrosion can have a catastrophic result. There is a chance of fatalities and environmental damage plus the huge cost of the downtime and lost productivity.

A study calculated the cost of downtime for two separate storage tanks:

Shell – Coating & corrosion problems in Crude Oil Tank

Size: 48 m diameter

Coating failure with severe pitting of floor plates

Downtime Cost: US$ 67,000/day

BP – Crude Oil Tank

Size: 78 m diameter

Coating failure with pitting of the floor plates

Downtime Cost: US$ 58,000/day

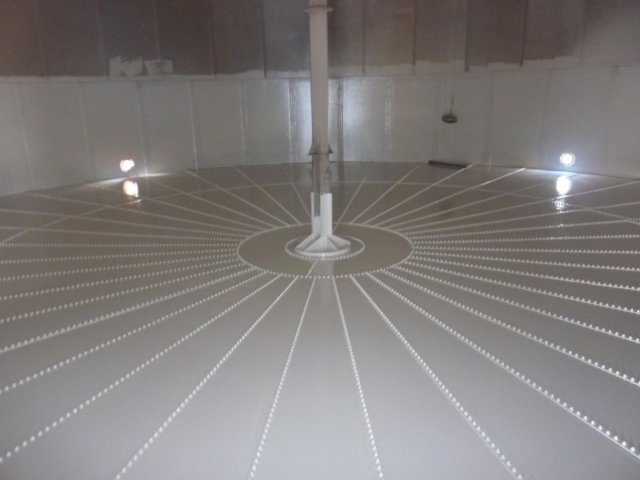

Chemcote have a total range of tank lining systems for your requirements. Your system will be designed to suit your tank type and surface condition. We will consider your expected lifetime to first maintenance. Other things to consider are, what is the product being stored. What is the temperature to be stored at. What is the duration of the storage. If the product to be stored is an aggressive chemical, we will specify a system to suit the pH level. If the product is an alcoholic beverage we have a coating specially formulated to protect this liquid asset for you.

Solvent-free glassflake epoxy.

Novolac epoxy glassflake

Fast cure, solvent free epoxy

Novolac epoxy with glassflake

High Temperature tank lining epoxy

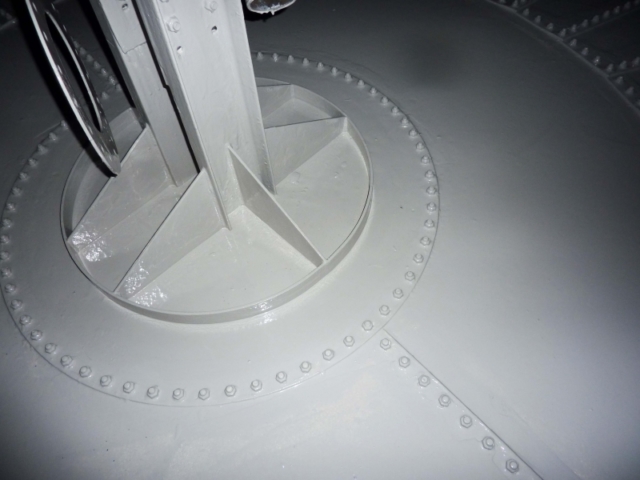

Chemcote has developed a range of vinylester coatings for long-term tank lining solutions. For over 30 years Chem-tect™ 300 series has proved itself as an outstanding choice for a storage tank lining. The Chem-tect™ range is 100% solid and reinforced with glassflake for fast-curing protective coating. Our range consists of:

Authorised Australian distributor of quality Chemco International Products