OVERVIEW: Chemcote was engaged to provide long term anti corrosion protection to a power generation customer’s sea water valves

INDUSTRY

ENVIRONMENT

Ambient sea water at high velocity

SUBSTRATE

Mild steel Duo Chek Valves

CHALLENGE

Carry out internal and external corrosion protection to provide longest possible life

SOLUTION

Glass flake filled vinyl ester provides exceptional low moisture vapour transmission rates compared with molecular filled coatings.

SCOPE

Remove excess rubber surrounding valve seat area

Ensure 2-3mm radius is provided where sharp edges exist

Mask and protect critical valve seat area

Abrasive blast to the required standards

Apply Chem-tect RB 364 @ 800 microns

Apply Epo-Chem RL 500PF in one coat @ 150 microns total DFT

Apply 1 coat of Epo-Chem RC 500GTC Jade Green

Unmask and touch up ready for delivery

PRODUCTS

RELATED CASE STUDIES

Refurbishment of Basket Strainer

After fabrication repairs After abrasive blasting, pitting visible Finished 300 Series Vinyl Ester Internals nearing completion OVERVIEW: Customer required long term corrosion protection for

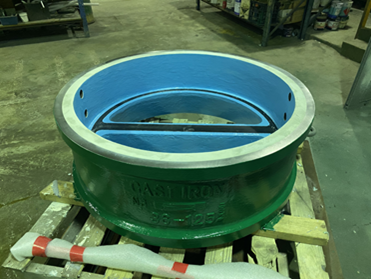

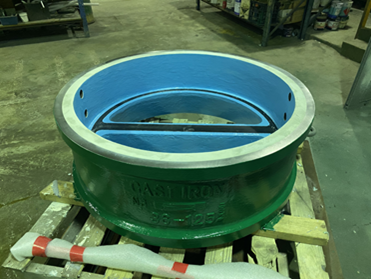

Duo Chek Valve

Masking and ready for abrasive blasting Application of multiple coats of RB364 internally Holiday testing to ensure coating continuity Coating complete OVERVIEW: Chemcote was

Pipe External Corrosion Protection

Existing corrosion, mech prep after UHPWB Application of spot primer Mid coat applied to affected areas After application of topcoat OVERVIEW: Chemcote was engaged