OVERVIEW: Customer required long term corrosion protection for significantly damaged 25 year old asset. A quick turn-around was required to meet project milestone targets and was achieved with minimal disruption to rolling mill operations. Chemcote ensure all QA and critical tolerances were adhered to provide the desired solution. No damage was visible at the six month follow up, confirming that Chemcote’s solution will deliver long term protection against future deterioration

INDUSTRY

ENVIRONMENT

60-70ºC Recirculated quench water used to flush mill scale

SUBSTRATE

25 year old Mild Steel Substrate

CHALLENGE

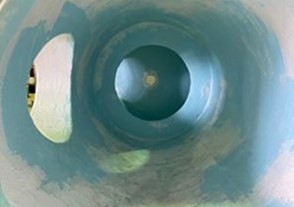

Heavy duty internal and external repair and protection for aged asset in a corrosive environment. Internal pitting from high temperature and mill scale. External corrosion caused by leaking flanges. Critical tolerances testing required to ensure basket fit to orifice plate.

SCOPE

Pre-machine rebates on all flanges

Abrasive blast internals

Apply glassflake filled vinyl ester to coat internals

Conduct QA including confirmation of DFT and high voltage continuity testing

Repair and rectify defects

Apply 3 coats of specially chosen products to ensure heavy duty external corrosion protection

Follow-up to ensure no damage during site installation

PRODUCTS

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce