OVERVIEW: A composite solution was used to restore the plant roof preventing moisture from entering and clogging up the entire fume suppression system. With the plant area back in service, the patched areas will provide years of protection in this aggressive environment. For more information on how we can help you please contact us.

INDUSTRY

ENVIRONMENT

Abrasive & corrosive coke dust environment

SUBSTRATE

30 year old mild steel suffering corrosion erosion on chute and roof structure

CHALLENGE

Carry out spark free surface preparation and composite repairs insitu to prevent water from blocking up outlet to the conveyor below

SOLUTION

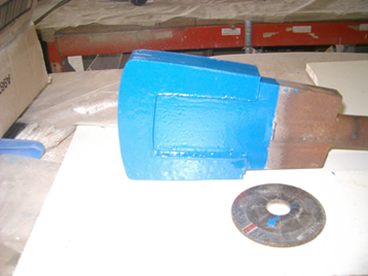

Abrasion Resistant RB 364CS coupled with alumina tiles was the ideal solution for this environment, consolidated with Basalt Fibre Wrap used for additional erosion protection

SCOPE

Mechanically clean using specially acquired needles for the needle gun and bristle blaster to prevent sparks

Application of 1 coat RB 364CS

Application of ceramic tile where appropriate

Basalt Fibre composite wrap consolidated with RB364CS

PRODUCTS

Chem-tect RB 364CS High temperature Vinylester Glassflake, Basalt Fibre Weave and Ceramic Systems

OUTCOME

Chemcote’s solution has extended the life of this asset by 12-24 months, and delivered a 30% improvement in functioning. Continuous high performance is guaranteed until our review at the next planned outage.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce