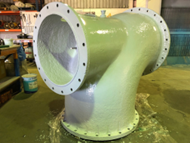

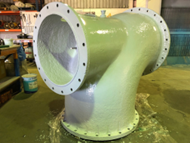

OVERVIEW: Chemcote were approached to improve corrosion resistance and improve fluid flow efficiency for this Power Generation Customer’s cast iron column pump

INDUSTRY

ENVIRONMENT

Ambient Salt Water

SUBSTRATE

Cast Iron Column Pump

CHALLENGE

Chemcote were brought in to carry out pump refurbishment after catastrophic failure of bearing causing the impeller to wear through the casing of the column pump

SOLUTION

Refurbish pump lining to extend service life using glass flake filled coatings, then top coated using RP 500 to improve fluid flow efficiency

SCOPE

Abrasive blast to AS.1627.4 to class 2.5

Masking and protection of critical tolerances and bush area on flange.

Pit filled to allow smooth transition and prevent coating defects

Sand smooth where necessary & application of RB364 to 1,000µm

Internal & external holiday testing to ensure coating continuity using the required voltage to suit the dry film thickness.

Application of the top coat Ceram-chem™ RP 500

PRODUCTS

Internals

Chem-tect™ RB 364 a glass flake filled vinyl ester

Ceram-chem™ RP 500 a ceramic filled epoxy

Externals

Epo-Chem™ RS 500P a surface and moisture tolerant primer

Epo-chem™ RA 500M a glass flake filled epoxy

OUTCOME

Improved corrosion resistance and fluid flow efficiency through the quality assurance process employed by Chemcote

RELATED CASE STUDIES

Fast Curing Abrasion Protection

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote OVERVIEW: Chemcote’s specialist team

Split Case Salt Water Pump Refurbishment

Apply protection to all machined surfaces Application of 1st coat RB 364 Apply Ceram-Chem RP500 Ready to return to service for another 15+ years of

Composite Pipe Repair

Flange is barely attached Repairs commence Repairs using composite weave mat Coating complete OVERVIEW: A power station client required corrosion protection for a 30-plus