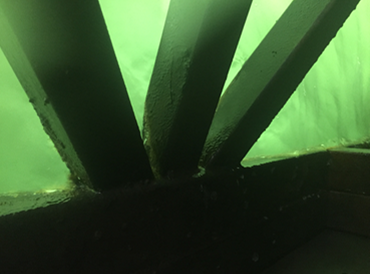

OVERVIEW: In the complete refurbishment of the underside of this floating structure, some areas were replaced. Other areas required repairs to be done in-situ by using underwater curing epoxies. A team of experienced divers applied the underwater curing Epo chem™ system, which is able to provide full coverage to surfaces where ideal surface preparation cannot be achieved.

INDUSTRY

ENVIRONMENT

Seawater

SUBSTRATE

Steel Brackets

CHALLENGE

The use of underwater curing epoxies was the most practical solution for this project. In the complete refurbishment of the underside of this floating structure, some areas were replaced. Other areas required repairs to be done in-situ by using underwater curing epoxies. A team of experienced divers applied the underwater curing epoxy coating.

SOLUTION

Chemco’s surface tolerant Epo chem™ system is able to provide full coverage to surfaces where ideal surface preparation cannot be achieved

SCOPE

Repairs were carried out at low tide where possible. Freshwater washing sections provide suitable surface preparation before applying the underwater curing epoxies

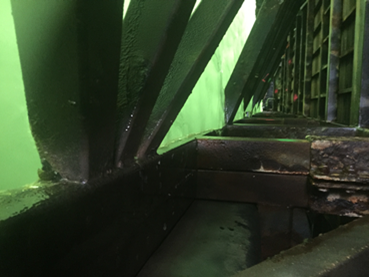

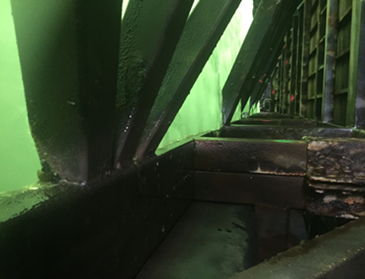

Removal of large, flaking corroded areas and coating back to bare steel by mechanical preparation using pneumatic needle gun, air chisel, scabbling and bristle blaster

Preparation underwater to St 2 by using an underwater grinder

Primer applied to create a continuous coating without pinholes wearing gloves and application mitts

Product lathered on in small, workable sections and cured overnight

The next day at low tide, the repair area above the surface washed with fresh water, then RA 500M, glass flake filled topcoat applied to above and below water sections

PRODUCTS

OUTCOME

By coating with Epo chem™, follow up inspections indicate the coating and repairs are still in good condition and is expected to exceed 10 years life in service

RELATED CASE STUDIES

Refurbishment of Basket Strainer

After fabrication repairs After abrasive blasting, pitting visible Finished 300 Series Vinyl Ester Internals nearing completion OVERVIEW: Customer required long term corrosion protection for

Duo Chek Valve

Masking and ready for abrasive blasting Application of multiple coats of RB364 internally Holiday testing to ensure coating continuity Coating complete OVERVIEW: Chemcote was

Pipe External Corrosion Protection

Existing corrosion, mech prep after UHPWB Application of spot primer Mid coat applied to affected areas After application of topcoat OVERVIEW: Chemcote was engaged