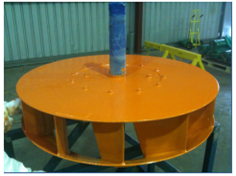

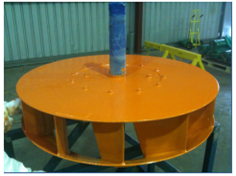

OVERVIEW: The fabricated carbon steel fan came under attack from atmospheric moisture and abrasion due to crystalline quartz dust in the hot air fumes that it was extracting. This resulted in costly unplanned shut-downs and reduced efficiency.

Chemcote supplied a coating to extend the life of the hot air impeller and reduce premature failures.

INDUSTRY

SUBSTRATE

Fabricated carbon steel fan

CHALLENGE

During the extraction of hot air fumes, the hot air impeller came under attack from atmospheric moisture and abrasion due to crystalline quartz dust in the air. This proved costly as it resulted in unplanned shut-downs and reduced efficiency. Chemcote was asked to supply a coating that would extend the life of the hot air impeller and reduce premature failures caused by abrasion and corrosion attack.

SOLUTION

Chemcote recommended a coating system suitable for corrosive and abrasive environments and with the ability to resist high temperatures. The low friction finish reduced foreign body build up and increased efficiency, reducing unplanned shutdowns

SCOPE

Pre-balance, grind welds, sharp edges & remove weld spatter

Abrasive Blast to class 2.5, minimum 50pm profile

Apply RS 500P in 1 coat

Apply RU 500 in 2 coats to a DFT of 400µm – 500µm

Post balance to clients required tolerance

PRODUCTS

OUTCOME

The hot air impeller has been operating with increased efficiency and without operational issues, the client is now looking at a program to line a further 19 fans based on this success using the RS 500P and RU 500 coating systems

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce