OVERVIEW: Maximum life expectancy was top on the list when this galvanising plant was looking for a new coating solution. We managed to save time and money during the installation of the long term solution. The customer mentioned he chose us due to our customer service during the initial contact stages of his enquiry.

INDUSTRY

ENVIRONMENT

Highly corrosive range of chemicals including Sodium Hydroxide and Hydrochloric Acid

SUBSTRATE

Concrete Bund in a chemical plant

CHALLENGE

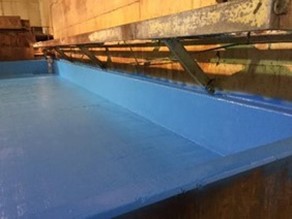

Upon inspection, the concrete bund was identified to be in a poor condition. This is due to the existing surface deteriorating after years of exposure. There are many locations on the bund that show a degree of damage and there is also evidence of chemical pooling. This seems to indicate that the fall is not functioning properly and, therefore, needs to be addressed and reinstated

SOLUTION

To ensure that the maximum life of the coating is achieved for our client, we reviewed the environment conditions, and specified the Chemco International Glass Flake Filled Chem-tect™ 300 series coatings. These coatings have been chosen as they offer excellent chemical and corrosion protection

SCOPE

Mobilise to site

Set up of dehumidification

Follow the Chemcote Concrete Coating surface preparation and priming Procedure

Reinstate the fall, and pit fill the holes using Chem-tect™ RA 300 series:

Application of 1st coat of RA 364 over entire surface

Application of 2nd coat of RA 364 to a DFT of 1000 nominal thickness for all areas

Carry out QA testing

Demobilise from site

PRODUCTS

OUTCOME

This coating project was completed on time, to budget and an inspection after 2 years has been recommended. Our Client was pleased with the result and the service.

RELATED CASE STUDIES

22 year old pipes coated with glass flake vinyl ester

Internal lining in excellent condition Abrasive blast externals Recoating of externals Recoating of externals in basement OVERVIEW: The pipes were originally coated internally using

Premature Failure of 316L Stainless Steel Pipes

Severe pitting after 2 months in service After abrasive blasting Damaged internals rebuilt and coated Externally applied caution OVERVIEW: New 316L pipe failed after

Corrosion protection ensures a long life for a new 98% Sulphuric Acid Bund

Newly constructed bund Primer application Application of final coat Job completed OVERVIEW: Chemcote was contracted to apply acid protection to a newly constructed delivery