OVERVIEW: This Power Generation customer approached Chemcote to save an estimated replacement cost of $500K for this 20 year old Bronze tube sheet.

This refurbishment is expected to extend the life for another 20 years, and corrosion protection has been provided to ancillary equipment.

INDUSTRY

ENVIRONMENT

40-60°C, sea water

SUBSTRATE

20 Year Old – Bronze tube sheet

CHALLENGE

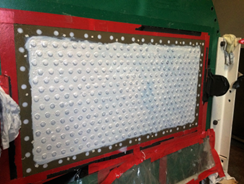

To provide a long term solution for the corroded tube ports and tube sheet

SOLUTION

A glass flake filled vinyl ester was applied to provide excellent permeation resistance and high dielectric strength

SCOPE

Tube internals were protected by inserting specially ordered silicon plugs to prevent abrasive blasting from damaging wall thickness. Abrasive blast as per required standard and remove silicon plugs and glue nylon tube inserts into position and then pitfill all deep cavities using RB 300 Series. We used the proprietary method to obtain a flat surface using RB 300 Series.

PRODUCTS

Chem-tect™ RB 364 a glass flake filled vinyl ester, provides excellent permeation resistance and high dielectric strength.

OUTCOME

Chemcote’s solution has extended the life of this asset by 12-24 months, and delivered a 30% improvement in functioning. Continuous high performance is guaranteed until our review at the next planned outage.

RELATED CASE STUDIES

Blast Furnace Recovery Turbine Repairs

Set up of Containment Masking before Blasting Spool Condition before Coating Aerial view of Outlet Spool from Shutoff Valve Completed Outlet Spool Internals Application of

Long Term Protection Of ISOtainers

Newly fabricated tank internals Tank Internals Confined space entry Completed tanks for delivery to customer OVERVIEW: The asset owner approached us to provide protection

Floating Restaurant Structure Repairs Using Underwater Curing Epoxies

Condition before surface preparation Mechanical Preparation Primer Application Second Coat applied OVERVIEW: In the complete refurbishment of the underside of this floating structure, some