OVERVIEW: The asset owner approached us to provide protection for their for their new investment, 304 Stainless Steel tanks which would contain 13-15% Sodium Hypochlorite

INDUSTRY

ENVIRONMENT

13-15% Sodium Hypochlorite

SUBSTRATE

New 304 Stainless Steel

CHALLENGE

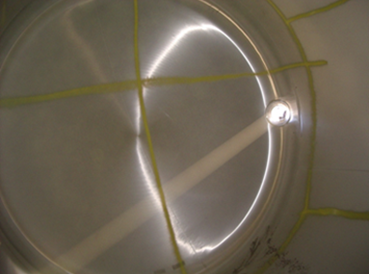

Asset owner required internal protection for their new ISOtainers which would be carrying sodium hypochlorite

SOLUTION

Abrasive blast and remove abrasive material

Application of RC 300 by spray application and stripe coating of all welds with a nominal thickness of 1,000μm

Confirm thickness and spark test

Apply top coat and post cure at 60degC for 6 hours

PRODUCTS

Chem-tect™ RC 300

Chem-tect ™ RA 364 glass flake reinforced vinyl ester

OUTCOME

The success of this project has allowed the asset owner long term peace of mind for their investment

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce