OVERVIEW: A customer was looking for a longer term solution to a corrosion erosion issue. Glass flake filled coatings provide excellent insulating properties against corrosion and the ceramic filled epoxy provides exceptional protection against erosion. The customer has found the pump now functions more efficiently when in use consuming less power allowing a payback period of the entire refurbishment to be only 14 months.

INDUSTRY

ENVIRONMENT

Dam Water

SUBSTRATE

Cast iron body

CHALLENGE

The client’s pump had dropped off in efficiency. This was due to the combination of corrosion and mechanical fatigue. The client was looking to improve efficiency and reduce power consumption.

SOLUTION

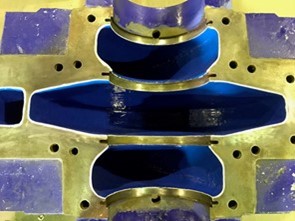

After 25+ years in service the substrate was heavily contaminated with metallic salts. This required heat treatment and a number of abrasive blasts to reduce salts below 25ppm. We then recommended the application of 2 coats of RB 332; a glass flake filled vinyl ester providing an excellent corrosion barrier and long term protection. We then applied 2 coats of RB 300GL to enhance fluid efficiency in turn reducing power consumption.

SCOPE

Strip and assess

Manufacture template to ensure mating faces match

Grind rebates on all flanged faces, allowing the coating to be applied on the flange face preventing future crevice corrosion

Protect critical dimensions

Abrasive blast and treat to reduce metallic salts by hot washing and re-abrasive blast

Apply corrosion barrier RB 332

QA included spark testing

Rebuild gland packing areas

Apply top coat of RB 300GL

PRODUCTS

OUTCOME

Pump repairs were achieved and by coating with RB 300, future corrosion is prevented with a reduced amount of friction through composite technology. The pump now functions more efficiently when in use and consumes less power, which led to carbon credits and greenhouse gas reduction. The payback period of the entire refurbishment worked out to be only 14 months.

RELATED CASE STUDIES

Preventing blockages using Chemcote Solution

Condition of surface before mechanical preparation RB 364 applied to spot abrasive blasted surfaces Pugmill externals Coating with InD Cote Previous Next OVERVIEW: A

Base Plate Corrosion Prevention

Repairs required Application of Primer Coating applied to affected areas After application of Topcoat Previous Next OVERVIEW: A 40 year old excess gas bleeder structure

Industrial Fallout Protection

After whip abrasive blasting Application of Epo-chem system to internals Basalt Fibre application on internals OVERVIEW: A steel production plant contracted Chemcote to reinforce