OVERVIEW: The pump was rebuilt and returned to service within a few weeks whereas a new replacement pump would have had a lead time of 20 weeks. The client was extremely happy thanks to the experienced Chemcote team and the exceptional corrosion resistance and machinability of the Chem-tect™ RB 300 series.

INDUSTRY

ENVIRONMENT

50-70°C 10-40μm abrasive particles from the dust catcher are disposed of in the pugmill and combined with water to suppress the dust creating an abrasive sludge

SUBSTRATE

Cast and machined carbon steel

CHALLENGE

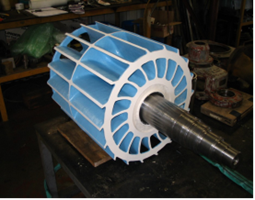

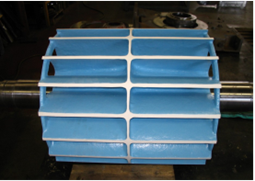

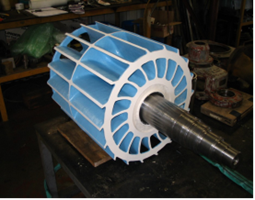

With an unprotected carbon steel pump, the rotor and barrel generally suffer rapid corrosion through contaminated water or acidic solvents used as sealant solutions. This leads to premature failure, inefficiency and costly repairs.

Chemcote’s challenge was to specify a coating that would repair the existing corrosion damage, restore the barrel and rotor back to the manufacturers original tolerances, extend the life of the Siemens pump, increase efficiency and prevent premature failures.

SOLUTION

Chemcote recommended the RB 300 series coating system with the ability to rebuild the pump’s corroded components back to the manufacturer’s original specifications

SCOPE

Pre-balance and pre-machine to allow for coating thickness

Abrasive blast to Class 2.5, minimum 50μm profile

Apply Chem-tect™ RB 300 to a DFT of 1000μm

Build up machined surfaces using RB 300 to a DFT of 3000μm

Post machine and post balance to clients required tolerances

Carry out DFT checks and holiday test to 8kV DC

PRODUCTS

OUTCOME

The vacuum pump was rebuilt and returned to service within a few weeks. A new replacement pump had a lead time of 20 weeks. The client was extremely happy thanks to the experienced Chemcote team and the exceptional qualities of the RB 300 series.

RELATED CASE STUDIES

Refurbishment of Basket Strainer

After fabrication repairs After abrasive blasting, pitting visible Finished 300 Series Vinyl Ester Internals nearing completion OVERVIEW: Customer required long term corrosion protection for

Duo Chek Valve

Masking and ready for abrasive blasting Application of multiple coats of RB364 internally Holiday testing to ensure coating continuity Coating complete OVERVIEW: Chemcote was

Pipe External Corrosion Protection

Existing corrosion, mech prep after UHPWB Application of spot primer Mid coat applied to affected areas After application of topcoat OVERVIEW: Chemcote was engaged