OVERVIEW: Pump has been in service for 15 + years providing the customer with peace of mind, and uninterrupted service, localised spot repairs were required due to mechanical damage

INDUSTRY

ENVIRONMENT

Ambient Sea Water

SUBSTRATE

Cast Iron body

CHALLENGE

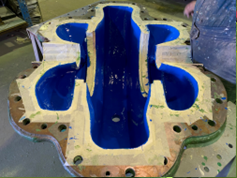

The original split case halves didn’t match with a misalignment of 35-40mm causing cavitation in the anti-swirl veins, we recommended a profile alignment and the addition of composite reinforcing

SOLUTION

Repair mechanical damage. We then applied RB 364, a glass flake filled vinyl ester consolidated with composite reinforcing to areas of the casing that had been damaged by external factors to return it to its original strength.

SCOPE

Onsite hotwash and scrub of internal lining to identify damage for repair

Whip & Spot Abrasive blast damaged areas

Application of RB 364 to bare metal areas of internals

Reprofile using chopped strand and RB 364

Apply RP 500 in two coats @ 250µm each

RL 500 PF to externals in two coats

PRODUCTS

RELATED CASE STUDIES

22 year old pipes coated with glass flake vinyl ester

Internal lining in excellent condition Abrasive blast externals Recoating of externals Recoating of externals in basement OVERVIEW: The pipes were originally coated internally using

Premature Failure of 316L Stainless Steel Pipes

Severe pitting after 2 months in service After abrasive blasting Damaged internals rebuilt and coated Externally applied caution OVERVIEW: New 316L pipe failed after

Corrosion protection ensures a long life for a new 98% Sulphuric Acid Bund

Newly constructed bund Primer application Application of final coat Job completed OVERVIEW: Chemcote was contracted to apply acid protection to a newly constructed delivery